Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Nylock Nut DIN985 DIN982

Views:

1000

The company has advanced high-speed cold heading machine machinery and equipment and automatic mesh belt furnace heat treatment production line, mainly producing bolts, nuts, washers, fully threaded studs, anchors, screws and DIN, BSW, ANIS, MS.Our factory also provides OEM, so we can provide you with the best quality and preferential prices.

Categories:

RELATED PRODUCTS

Product introduction

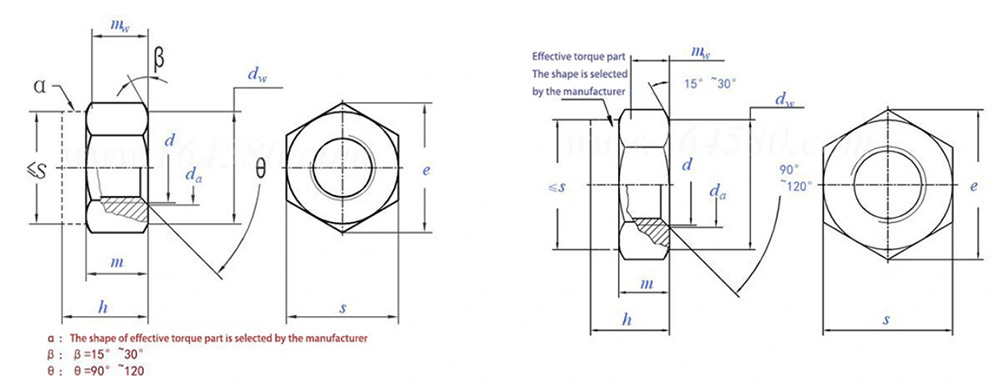

Title:Nylock Nut DIN985 DIN982

Size:M5-M50

GRADE:4.8/8.8/10.9/12.9

Material:carbon steel/stainless steel

Surface treatment:natural color/black/galvanized/hot-dip galvanized/Dacromet/Teflon, etc

Standard:DIN/ISO/ANSI/BS/AS/GOST/EN

Packaging:bags/cardboard boxes/wooden pallets/customer needs

| DIN982 Thread specification |

M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | |||

| d | ||||||||||||||

| P | pitch | coarse teeth | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | |

| fine teeth | / | / | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 2 | |||

| fine teeth | / | / | / | 1.25 | 1.25 | / | / | 1.5 | 1.5 | 1.5 | / | |||

| da | minimum | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | ||

| maximum value | 6.75 | 7.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 21.6 | 23.7 | 25.9 | |||

| dw | minimum | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | 24.9 | 27.7 | 29.5 | 33.2 | ||

| e | minimum | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 | 32.95 | 35.03 | 39.55 | ||

| h | max = nominal | 8 | 8.5 | 9.5 | 11.5 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | ||

| minimum | 7.7 | 8.2 | 9.14 | 11.14 | 13.64 | 15.3 | 17.3 | 19.16 | 20.7 | 23.7 | 26.7 | |||

| m | minimum | 4.9 | 6.14 | 6.44 | 8.04 | 10.37 | 12.1 | 14.1 | 15.1 | 16.9 | 18.1 | 20.2 | ||

| mw | minimum | 3.92 | 4.91 | 5.15 | 6.43 | 8.3 | 9.68 | 11.28 | 12.08 | 13.52 | 14.48 | 16.16 | ||

| s | max = nominal | 10 | 11 | 13 | 17 | 19 | 22 | 23 | 27 | 30 | 32 | 36 | ||

| minimum | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 | 29.16 | 31 | 35 | |||

| Thousand pieces (steel)≈kg | 3.1 | 3.2 | 6 | 11.7 | 16.6 | 21 | 37.8 | 51.6 | 68 | 86 | 127 | |||

| DIN985 Thread size |

M3 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | |||

| d | ||||||||||||||

| P | pitch | coarse teeth | 0.5 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | |

| fine teeth 1 | / | / | / | / | / | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | |||

| fine teeth 2 | / | / | / | / | / | / | 1.25 | 1.25 | / | / | 1.5 | |||

| d a | minimum | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | ||

| maximum value | 3.45 | 4.6 | 5.75 | 6.75 | 7.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | |||

| dw | minimum | 4.6 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | 24.9 | ||

| e | minimum | 6.01 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 | ||

| h | max = nominal | 4 | 5 | 5 | 6 | 7.5 | 8 | 10 | 12 | 14 | 16 | 18.5 | ||

| minimum | 3.7 | 4.7 | 4.7 | 5.7 | 7.14 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 17.66 | |||

| m | minimum | 2.4 | 2.9 | 3.2 | 4 | 4.7 | 5.5 | 6.5 | 8 | 9.5 | 10.5 | 13 | ||

| mw | minimum | 1.65 | 2.2 | 2.75 | 3.3 | 3.85 | 4.4 | 5.5 | 6.6 | 7.7 | 8.8 | 9.9 | ||

| s | max = nominal | 5.5 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | 27 | ||

| minimum | 5.32 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 | |||

| 1000 pieces weight kg | 0.5 | 1 | 1.4 | 2.4 | 3 | 5.1 | 10.6 | 17.2 | 26 | 34 | 45 | |||

| Thread size | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | |||

| d | ||||||||||||||

| P | pitch | coarse teeth | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | |

| fine teeth 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | |||

| fine teeth 2 | 1.5 | 1.5 | / | / | / | / | / | / | / | / | / | |||

| d a | minimum | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | ||

| maximum value | 21.6 | 23.7 | 25.9 | 29.1 | 32.4 | 35.6 | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | |||

| dw | minimum | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.6 | 51.1 | 55.9 | 60.6 | 64.7 | 69.4 | ||

| e | minimum | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 72.09 | 76.95 | 82.6 | ||

| h | max = nominal | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | ||

| minimum | 18.7 | 20.7 | 22.7 | 25.7 | 28.7 | 31.4 | 34.4 | 37.4 | 40.4 | 43.4 | 46.4 | |||

| m | minimum | 14 | 15 | 15 | 17 | 19 | 22 | 25 | 27 | 29 | 32 | 36 | ||

| mw | minimum | 11 | 12.2 | 13.2 | 14.8 | 16.5 | 18.2 | 19.8 | 21.5 | 23.1 | 24.8 | 26.5 | ||

| s | max = nominal | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | ||

| minimum | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.8 | 68.1 | 73.1 | |||

| 1000 pieces weight kg | 65 | 75 | 100 | 162 | 212 | 317 | 415 | 499 | 628 | 771 | 998 | |||

A nylock nut is a remarkable fastening solution with unique features. It is designed to provide enhanced security and reliability.

The key characteristic of a nylock nut is the nylon insert. This insert creates a prevailing torque, preventing the nut from loosening due to vibration or other forces. It acts as a built-in lock, reducing the need for additional locking devices.

Nylock nuts are highly durable and can withstand various environmental conditions. They are often used in applications where vibration or movement is a concern, such as in automotive, machinery, and aerospace industries.

The nylon insert also helps to protect the threads and reduces friction, making installation and removal relatively easy. It provides a smooth and stable connection.

These nuts come in different sizes and materials to meet specific requirements. They are available in standard and metric thread sizes.

The combination of the metal nut and the nylon insert offers a balance of strength and locking ability. It ensures that the fastened components remain securely in place.

Whether used in heavy-duty industrial equipment or everyday consumer products, nylock nuts play a crucial role in maintaining the integrity of assemblies. Their ability to resist loosening and provide reliable fastening makes them a preferred choice in many engineering and manufacturing applications. They are a simple yet effective solution for ensuring long-term stability and performance.

Company introduction

Handan Wangsheng Fastener Co., Ltd. was officially established in 2007 and islocated in Handan City, Hebei Province, China's largest fastener production base.The enterprise covers an area of over 7000 square meters, employs over 200 peopleand has more than 100 advanced production equipment in China. lt is a modernfastener manufacturing enterprise that integrates production and manufacturinge-commerce operation, and intelligent warehousing.

Honorary certificate

Production process

Previous:

Next:

ONLINE CONSULTING

RELATED PRODUCTS